Product Overview

Type: Filter-dryer, usually refers to a device that integrates filtering and drying functions, used for compressed air post-processing.

Principle: Combines filtering and drying technologies to remove moisture, oil, impurities and dust from compressed air.

Main functions:

Filtration: Remove solid particles, oil droplets, water droplets and impurities from compressed air.

Drying: Reduce the dew point temperature of compressed air and remove moisture.

Technical Features

Integrated design: The filtering and drying functions are integrated into one unit, with a compact structure and small footprint.

High-efficiency filtration: A multi-stage filtration system is usually used, such as:

- Pre-filter: Filters out larger particles and impurities.

- Oil-water separation filter: Filters out oil droplets and water droplets.

- Fine filter: Filters out finer particles and oil mist to achieve higher filtration accuracy.

Drying technology: RISHENG's filter dryers may use one or a combination of the following drying technologies:

- Freeze drying: Use the refrigeration cycle to reduce the temperature of the compressed air, so that the water condenses and is discharged.

- Adsorption drying: Use adsorbents (such as activated alumina, molecular sieves, etc.) to adsorb moisture in the compressed air.

High-quality filter element: Use high-efficiency filter materials to ensure filtering effect and service life.

Automatic drainage: Equipped with an automatic drainer, the condensed water is discharged regularly to avoid water accumulation.

Intelligent control: Some models may be equipped with an intelligent control system to monitor the compressed air parameters in real time and automatically adjust the operating status.

Application Fields

Electronic manufacturing: Provide clean and dry compressed air to protect electronic components.

Food processing: Ensure that compressed air meets food hygiene standards.

Pharmaceutical manufacturing: Provide sterile compressed air for drug production and packaging.

Textile printing and dyeing: Provide clean and dry compressed air to improve product quality.

Automobile manufacturing: Used in painting, assembly and other processes.

Mechanical equipment: Used to drive pneumatic tools and control systems.

Other fields: Such as laboratories, hospitals and other occasions that require clean and dry compressed air.

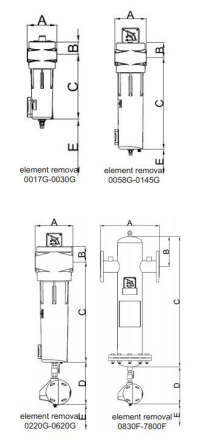

User-friendly design with flange shell

Flange shells adopt user-friendly design, convenient for replacement of filter elements.

| Model | Capacity | Air | Dimension (mm) | Weight |  |

|||||

| m³/min | CFM | Connection | A | B | C | D | E | (kg) | ||

| RSG-**-0017G/V2 | 1 | 35 | Rc1/2" | 89 | 40 | 158 | / | 95 | 1.1 | |

| RSG-**-0030G/V2 | 1.8 | 64 | Rc1/2" | 89 | 40 | 192 | / | 130 | 1.5 | |

| RSG-**-0058G/V2 | 3.6 | 127 | Rc3/4" | 120 | 55 | 252 | / | 172 | 2.5 | |

| RSG-**-0080G/V2 | 4.8 | 169 | Rc1" | 120 | 55 | 352 | / | 272 | 3.2 | |

| RSG-**-0145G/V2 | 8.7 | 307 | Rc1-1/2" | 120 | 55 | 352 | / | 272 | 3.2 | |

| RSG-**-0220G/V2 | 13.2 | 466 | Rc2" | 162 | 64 | 468 | 180 | 320 | 6.6 | |

| RSG-**-0330G/V2 | 20 | 706 | Rc2" | 162 | 64 | 742 | 180 | 625 | 10.9 | |

| RSG-**-0430G/V2 | 25.8 | 911 | Rc3" | 200 | 78 | 500 | 180 | 650 | 12.9 | |

| RSG-**-0620G/V2 | 40 | 1412 | Rc3" | 200 | 78 | 757 | 180 | 650 | 17.5 | |

| RSG-**-0830F/V2 | 50 | 1766 | DN100 | 493 | 263 | 1119 | 220 | 650 | 115 | |

| RSG-**-1000F/V2 | 60 | 2119 | DN100 | 493 | 263 | 1119 | 220 | 650 | 115 | |

| RSG-**-1200F/V2 | 70 | 2472 | DN125 | 617 | 290 | 1179 | 220 | 650 | 145 | |

| RSG-**-1300F/V2 | 80 | 2825 | DN125 | 617 | 290 | 1179 | 220 | 650 | 150 | |

| RSG-**-1950F/V2 | 120 | 4237 | DN150 | 617 | 299 | 1206 | 220 | 650 | 195 | |

| RSG-**-2500F/V2 | 150 | 5297 | DN200 | 666 | 343 | 1354 | 220 | 650 | 240 | |

| RSG-**-3250F/V2 | 200 | 7062 | DN200 | 740 | 368 | 1459 | 220 | 650 | 380 | |

| RSG-**-4650F/V2 | 280 | 9887 | DN250 | 800 | 420 | 1583 | 220 | 650 | 450 | |

| RSG-**-5200F/V2 | 312 | 11017 | DN250 | 800 | 420 | 1583 | 220 | 650 | 455 | |

| RSG-**-7800F/V2 | 468 | 16525 | DN300 | 906 | 476 | 1646 | 220 | 650 | 850 | |

FAQ

1. How does it remove moisture and contaminants from compressed air?

It removes moisture and contaminants from compressed air through a combination of filtration and drying technologies. The compressed air first passes through a pre-filter to remove larger particles and impurities. Then, it goes through a drying process, typically using a refrigerated or desiccant method, to lower the air's dew point and remove moisture. Finally, a post-filter further refines the air by capturing any remaining fine particles and oil vapors.

2. What are the key technical specifications that determine its suitability for different applications?

Its key technical specifications include flow rate, pressure range, inlet and outlet connections, power consumption, and dew point. These specifications determine its suitability for different applications by ensuring it can handle the required volume of compressed air at the specified pressure, while achieving the desired level of dryness.

3. In which industries or applications is it commonly used?

It is commonly used in various industries such as manufacturing, automotive, electronics, food and beverage, pharmaceuticals, and textiles. These industries require clean and dry compressed air for processes like painting, assembly, instrument air, packaging, and controlling pneumatic tools.

4. What kind of maintenance does it require to ensure optimal performance?

It requires regular maintenance, including replacing filter elements, checking the condensate drain, and inspecting the refrigeration or desiccant system (depending on the type of dryer). Regular maintenance ensures optimal performance, prevents clogging, and extends the lifespan of it.

5. How does it compare to other types of compressed air dryers, such as refrigerated dryers or desiccant dryers?

It offers the advantage of integrating both filtration and drying in one unit, which can simplify the compressed air system and save space. Compared to standalone refrigerated dryers, it provides additional filtration. Compared to standalone desiccant dryers, it may offer a more energy-efficient solution for applications requiring moderate dew points.

6. What are the initial and operating costs associated with it?

The initial cost of it includes the purchase price and installation cost. The operating costs include energy consumption, maintenance expenses (filter replacements, etc.), and potential downtime for maintenance. The overall cost-effectiveness depends on factors like its efficiency, lifespan, and the specific requirements of the application.